Founded in 1902 as American Bag & Paper, American Packaging Corporation provides bags, pouches, laminations, coatings and printing technologies across a range of markets, from pet food and snacks to fresh produce and liquids. We caught up with Jeff Travis, Manager of Sustainability and Innovation, ahead of his appearance at the Sustainability in Packaging Conference to discuss how APC’s products support the circular economy, the acronym that guides the company’s innovation process and the importance of life cycle analyses.

Tell us about your role and how that fits into the work of APC.

My official title is Manager of Innovation and Sustainability. American Packaging Corporation is a family-owned, flexible packaging converter. Our packaging goes to many of the brands that you see on the store shelves today, all designed to meet customer requirements. The expectation with those brands is beyond servicing their traditional packaging needs. It becomes an expectation that we provide incremental value to take these products to new levels.

The goal is to give the end customer higher derived value for the package, product differentiation or, in the case of sustainability, enhanced end-of-life options. On the innovation side, we assist our brands with enhancing the value of the product. It could be new functionality or features to a package such as the addition of a handle, a new re-closure, different ways of dispensing the product, or even ways to promote engagement with the consumer.

Sustainability is very akin to innovation. As the materials and process technologies are emerging rapidly, we need to be aware of the breadth of options available that can give our customers the ability to utilize the products without compromising their manufacturing efficiencies, package integrity and product shelf life. Both of these functions are critical; APC needs to supply continuous value to our customers and advance their product platforms, integrating the additional value into the packaging to enhance the consumer desire for the product.

The expectation with those brands is beyond servicing their traditional packaging needs. It becomes an expectation that we provide incremental value to take these products to new levels.

What are some of the guiding principles for innovation at APC?

We use a very flexible approach to innovation, and we need our process to be very simple and efficient. At APC, we have the Center for Packaging Innovation located in Columbus, Wisconsin. Once we have a project that’s kicked off, we agree on the scope and deliverables. You can use the acronym INVENT to describe the process.

There’s Ideation; a group of people sit around a table sharing samples of products they purchased at a store and start ideating about how specific elements can be incorporated into the new design. At this point, no idea is a bad idea; we jot down as many as possible. Then there’s Navigation; with any great ideation session, there’s a broad list of ideas. It’s important that these be grouped into common themes or ideas that are focused around a particular element of the innovation. After the grouping exercise is Visualizing–it is often helpful to expand upon the ideas and translate these into sketches. APC has a talented industrial designer that can take these concepts and turn them into visual references to aid the participants in better understanding the concepts. The Evaluating step involves a review of the visualized ideas and refinement or clarification of the intent. Narrowing the focus involves narrowing down these concepts to a manageable few, ensuring that the chosen concepts fit within the original scope defined for the project.

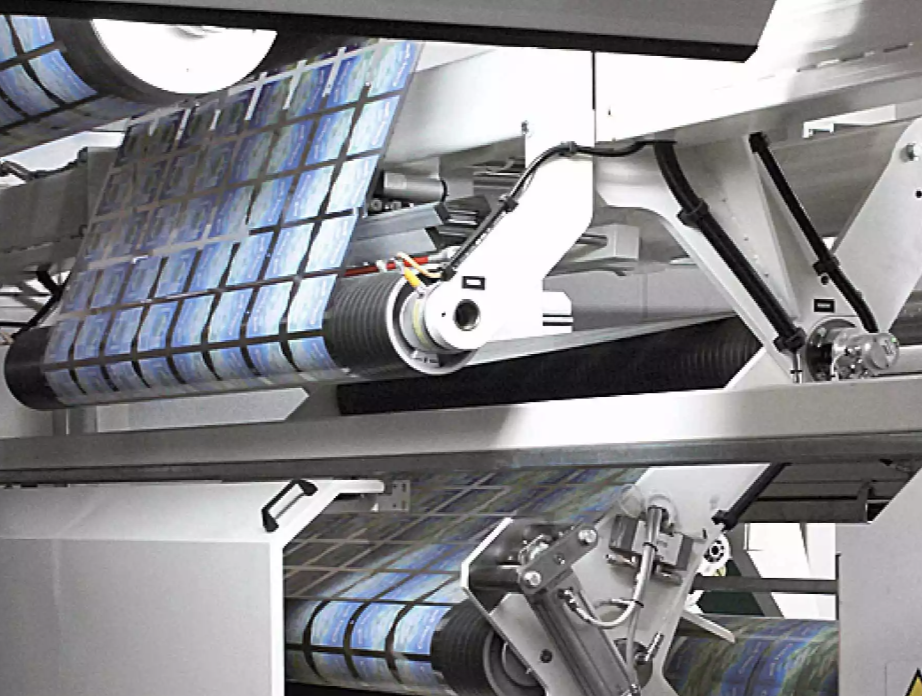

Then there’s Testing the product. This includes hand mock-ups and prototyping, where the customers get a hands-on perspective. Our prototype laboratory has a number of laminates, zippers, sealers, and tools that can be used to form packaging of the desired shape and function. When the prototypes are verified and confirmed to meet the requirements, we move on to the fully-functional prototype stage. We print the material and form it using our prototype capabilities, as this is the best way for the brands to fully visualize how it may look and function from the consumer’s perspective. Once the prototype is approved, we can move it forward in a number of ways. We have a digital press that can be utilized for small-scale testing, or we can take it to our large format presses.

What are some recent developments at APC that have you excited for the future?

We just made a significant investment in pouching equipment for the pet food industry. We can now do anything from eight to 32-pound bags. These are brand-new lines that we’re working on with customers, getting qualified as we speak. That’s enabled us to move to an entirely new segment that we did not participate in before.

We’re taking areas where there used to be a multi-material and doing assessments to make those fully recyclable. Again, sustainability is very exciting to me. We’re doing things on the recycling side, post-consumer recycled content, renewable content, design for compost, all those things. There’s a lot of activity, and it’s just so exciting to see the energy that our customers have to implement these. Sometimes it’s a bit of a mad rush, but it’s just amazing to see. 2025 goals seem so far out there, but there’s so much preparation ahead of that and it’s moving very quickly.

How are sustainability initiatives manifested on the technical side of APC’s operations?

APC has a broad portfolio of sustainable solutions under what we call our RE™ platform. This is really designed to support the circular economy, which includes source reduction. Source reduction can include conversion from rigid formats to flexible, product right-sizing, down-gauging and material substitutions where more efficient materials are available.

Products can be designed for recycling, which includes the development of materials that are compatible with a recycling stream. They can be made from post-consumer recycled content using products that have served their useful life back in the new products, or renewable and bio content using materials that can reduce dependence on fossil-based feedstocks. There are also materials designed for compost, which includes the development of products that could be broken down in the appropriate environment. All of these solutions are all relatively new within the last five years and require significant research and development because the goal we have is to provide solutions to our customers that could be implemented without significant disruption to their manufacturing operations.

APC has a broad portfolio of sustainable solutions under what we call our RE™ platform. This is really designed to support the circular economy.

What are some keys to improving the overall sustainability of flexible packaging?

Some of the big things are reducing the carbon footprint, enhancing the ability to recycle, increasing the breadth of materials that can be recycled and developing compostable options for packaging nutrient-contaminated products. There are certainly challenges. For example, the recycling of flexible packaging is limited to single-stream, to polyethylene, to front-of-store drop-off. In other parts of the world, both polyethylene and polypropylene packaging is often collected for recycling. Ultimately, these materials comprise a significant quantity of the packaging used in the snack markets today.

Unfortunately, because there isn’t a polypropylene stream in the U.S. right now, we’re having to reinvent packaging to fit the options that are currently available on the compost side. The challenge is many compost facilities are not accepting compostable packaging. Another burden is challenging infrastructure. Not all residents or businesses across states or across the country have the same options available to them. Fortunately, organizations like the U.S. Plastics Pact are making concerted efforts to focus on more regional needs.

What are some recurring challenges you face in the flexible packaging sector?

One of the most significant challenges I see is the lack of consumer awareness and knowledge about the value of flexible packaging. Life cycle analysis is one of those tools that can be used to compare different packaging alternatives. In the majority of cases, flexible packaging offers the smallest footprint, extends shelf life and barrier protection, uses fewer natural resources in the manufacturing process, offers greater transportation efficiencies and less fossil fuel consumption.

Conversely, flexible packaging is challenged due to its lightweight nature and the complication with existing infrastructure. You need to collect considerably more materials to justify the economics of investing in infrastructure that can handle both the current rigid stream and the flexible formats. Fortunately, efforts like the Materials Recovery For the Future project are making significant progress that shows both rigids and flexibles can be collected within a material recovery facility.

In the majority of cases, flexible packaging offers the smallest footprint, extends shelf life and barrier protection, uses fewer natural resources in the manufacturing process, offers greater transportation efficiencies and less fossil fuel consumption.

What are you looking forward to at the Sustainability in Packaging Conference?

I’ve attended this conference for a number of years and find it of significant value. The perspectives you get are evenly split between brands, local governments, NGOs, private industry, material producers, converters, et cetera. You get a broad perspective of everything that’s going on because the impacts upon each of those groups are different.

It’s important to hear everyone’s perspective, and I find that very important in my role because I dialogue regularly with customers and internal groups to help them understand the status of things and where we need to go. This information is leading edge; it’s insight that we all need to move things along.